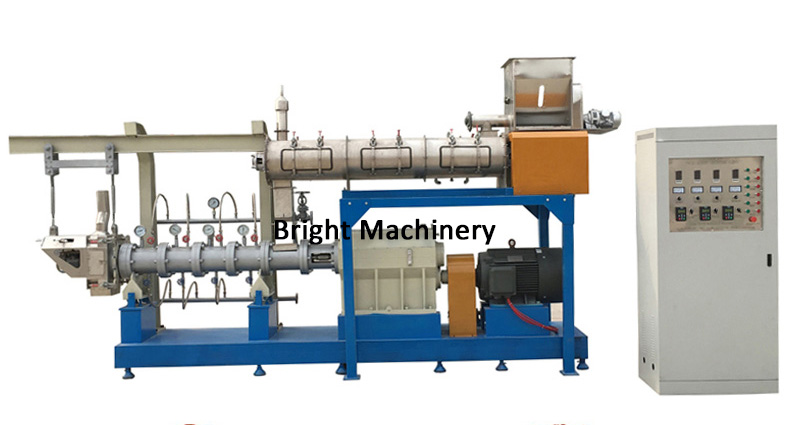

Production of Fish and Shrimp Feed with the Extruder

Production of Fish and Shrimp Feed with the Extruder

In the fish and shrimp feed production process, the raw materials undergo the process steps of weighing, fine grinding, mixing, extrusion, drying, vacuum coating, cooling and packaging. Expanded fish and shrimp feed is a new technology which has been studied in recent years. The advantages of the product are many:

1. It can float on the surface of water because of its porous property.

2. The feed temperature can be as high as 165℃ in the fish feed extrusion process, which can make the feed disinfect and sterilize well.

3. Because starch in the material is partially gelatinized, it is easy to be digested and absorbed by fish, which can improve the utilization rate of products.

4. Different fish feed extrusion conditions can be determined according to material characteristics, which can not only reduce heat treatment time and maintain nutrients to the greatest extent, but also make water-soluble nutrients difficult to hydrolyze after extrusion and color film treatment, which can greatly improve feed conversion.

5. The moisture content of the product fish feed after forced drying can be as low as 6-8%, which can effectively prolong the storage time.

företag:

adress:

telefon:

e - post:

skype.

Whatapp/Wechat: